Our Process

The Mandujano Difference

The Mandujano Difference

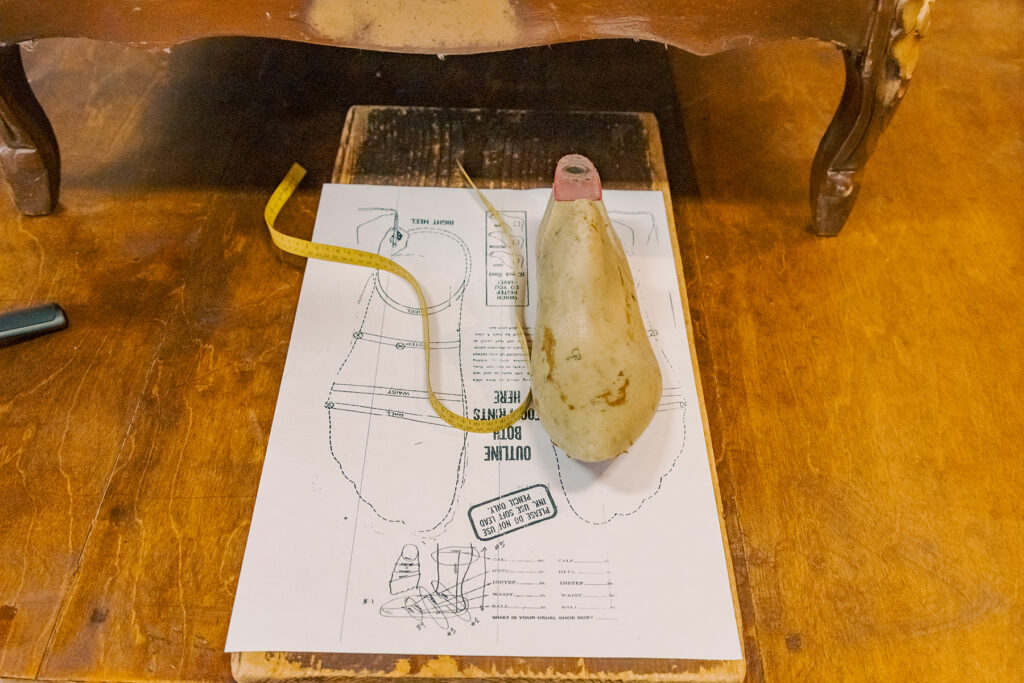

The Mandujano DifferenceTaking Measurements

The Mandujano Difference

The Mandujano DifferencePreparing Your Custom Last

The last is a polyethylene form and is shaped like your foot. This determines the size and shape of the toe and how high of a heel your boot will take. Making a boot to fit comfortably depends on the lasting techniques Mandujano prides itself from. The Mandujano Difference

The Mandujano DifferenceSkin Matching

Mandujano is proud of choosing grade A high quality skins for boot making. Two alligator skins are used when making a pair of boots. It is critical to match each pair of skins. Our boot makers examine each skin’s characteristics such as tile size and pattern markings. Each skin is unique as finger print. Mandujano compares about 10-15 skins at a time to properly match each pair. The Mandujano Difference

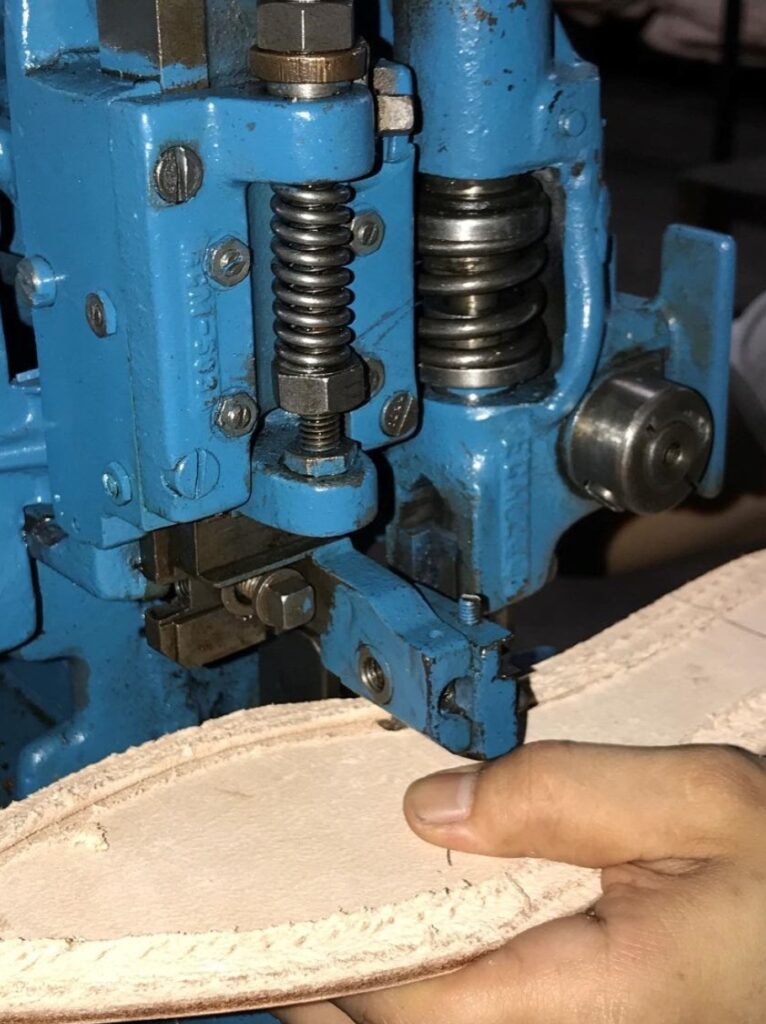

The Mandujano DifferenceCutting

The cutting process is the most important and critical part of crafting a boot. If the skin is not cut properly it can affect the entire process. Once the leather is precisely aligned, a clicker machine is used which applies at least 15 tons of pressure on the die and leather in order to create an exact cut. It takes a great deal of skill and precision in order to cut the leather. The Mandujano Difference

The Mandujano DifferenceVamp and Shaft Attachment

The vamp or the foot portion of the boot is skillfully placed and precisely hand guided through the needle and sewn onto the tops. The counter or heel portion of the boot is also sewn onto the tops of the boot.

Screenshot The Mandujano DifferenceGemming vs Channeling

Gemming is used as an attachment point between the insole and welt of most Goodyear welted footwear using a cotton rib. This method will minimize the lifespan of the boot or shoe. After 2-3 resoles, the gemming will break (either the rib or the cement will come loose) and then make the boot un-resolable. Today more than 95% of all goodyear welted boots are made using this technique to cut cost and speed up the manufacturing process.

Our version of a Goodyear welt takes it a step further. Our leather insoles are channeled with a machine to allow for a flap of leather to be created around the perimeter. This creates a stronger bond between the internal components of the boot. We feel our method of channeling our leather insole is a huge step in maintaining a boot that is constructed using as much leather as possible. Although this process is difficult and very labor intensive, we feel this technique further separates our products from other bootmakers and is the highest quality method available.

The Mandujano Difference

The Mandujano DifferenceLasting

The last is a polyethylene form and is shaped like your foot. This determines the size and shape of the toe and how high of a heel your boot will take. Making a boot to fit comfortably depends on the lasting techniques Mandujano prides its self from. The upper is wet with water, pulled over the last and tacked securely with temporary tacks. This is a very physical process and takes a great amount of experience to perfectly complete this task.

Screenshot The Mandujano DifferenceGoodyear Welt

A Goodyear Welt shoe or Goodyear Welt boot is made using a strip of leather that runs along the perimeter of the outsole. A skilled boot maker is required to successfully perform this critical task. At Mandujano, we break a sweat to ensure that while your custom boots may take a few weeks to be completed they will however last a lifetime. Our ultimate goal is for you to be wearing your good pair of Mandujano leather insole goodyear welted boots, in ten to fifteen years from the day you receive them.

Screenshot

Screenshot The Mandujano DifferenceLemonwood Pegging

Lemonwood pegs are securely hammered into holes made in the leather outsole to keep the steel shank, insole and outsole in place. They are more durable then brass nails as brass nails are forced out of the outsole as it swells when exposed to water. Lemon wood pegs expand and contract when exposed to moisture almost at an identical rate as leather. Lemonwood pegs date back to the old world of boot making and are the gold standard when making custom made boots.

The Mandujano Difference

The Mandujano DifferenceEdge Trimming

Using a free hand motion against a very sharp set of spinning blades, we trim the edge of the outsole and the edge of the welt to its final shape.

Screenshot The Mandujano DifferenceHeel Attachment

The heel attachment process is performed with great precision. Manual heel attachment through the outside portion of the heel may leave nails exposed in the insole. Our machine pneumatically pushes the threaded nails from the inside of your boot through the leather insole, leather outsole and heel base. This method eliminates nail exposure and prohibits any squeaking and allows that heel to be seated properly.

The Mandujano Difference

The Mandujano DifferenceBottom Staining

The edge of the heel and bottom of the outsole are stained. Using friction with waxed spinning brushes brings the bottom of the outsole and the edge of the sole and heel to a high-gloss shine.

The Mandujano Difference

The Mandujano DifferenceTouch Up Artist

We clean the boot of any dust of foreign material that by have adhered to the boot as it was being crafted. We touch up any small flaws in the boot in the leather and we apply a base coat which will act as a binder for the final polish.